The automotive industry is on the move. New technologies and increasing globalization of the market are putting pressure on producers and suppliers alike. This makes it all the more crucial to have a reliable, flexible and experienced partner at your side for automotive profiles as well.

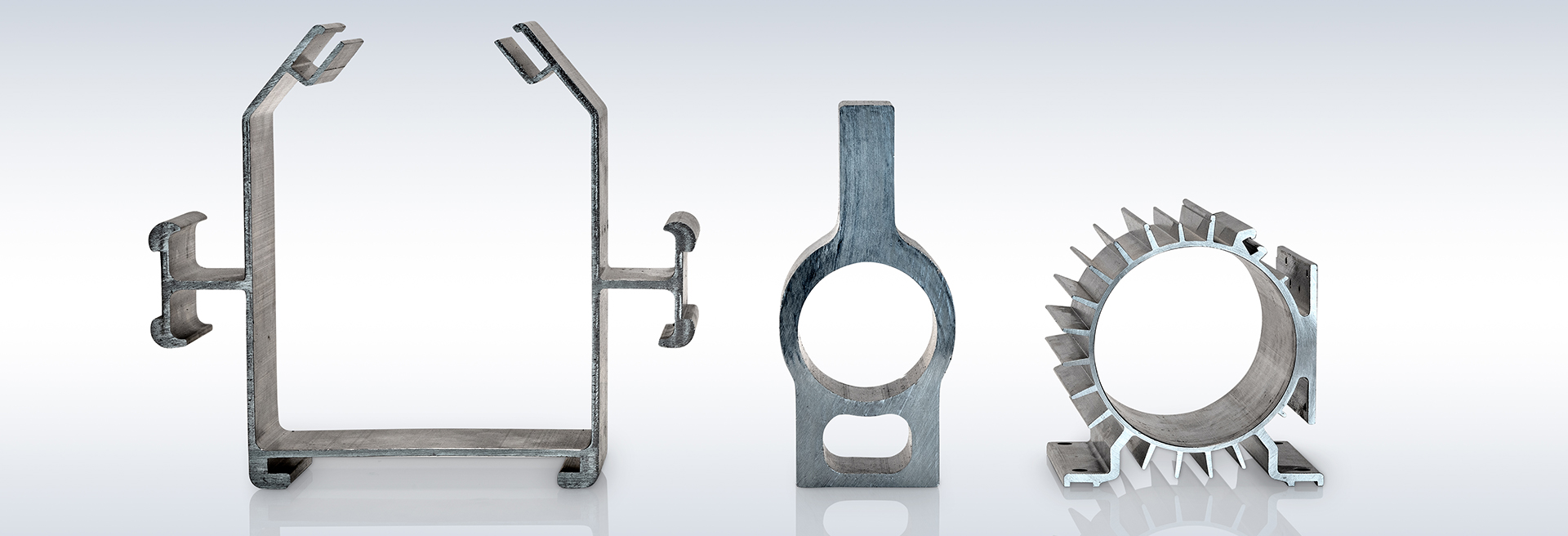

IsoProfil offers you all of this and, through these strengths, helps you to produce as efficiently as possible. Within this framework, our production range naturally includes all common profiles for automotive such as door frames, window frames, fittings and car bodies.

The most important criterion for market success is still quality. Automotive manufacturers in particular accept only the highest precision for good reason. In order not only to meet these high demands of our customers, but even to exceed them, we rely exclusively on state-of-the-art processes for the production of automotive profiles.

In the modern CAD environment, our experienced engineers plan the required profiles exactly according to customer requirements before they are produced to the millimeter with our powerful CNC machines.

Thanks to our manufacturing expertise, which has been continuously expanded over the years, we can also support our customers in the fundamental design of automotive profiles. Often, not only weight but also material can be saved by an appropriate design, which reduces production costs and makes the component more attractive, because: Less weight means lower energy consumption for the planned vehicle.

In addition, weight can be saved by choosing the right material. We are experts in the production of aluminum profiles for automotive and know the outstanding properties of this lightweight metal. Despite its low weight, it offers high stability, is corrosion-resistant and has an attractive high-gloss appearance. These properties make aluminum profiles particularly interesting for automotive.

We know our way around the automotive industry and how tightly timed the supply chains are in this sector. To provide our customers with the best possible support, we not only promise them one hundred percent adherence to deadlines, but also respond promptly and flexibly to customer requests. In this way, we can also handle acute inquiries and thus noticeably relieve our customers. This is made possible by our good connections to excellent suppliers and a network of experts.

Do you still have questions about our profiles for automotive or would you like to start an inquiry? Then it is best to contact our experts right away. We look forward to hearing from you!

Learn more about the manufacturing processes we use