In principle, all the surfaces of electroplatable materials, i.e brass, aluminium, copper, zinc, stainless steel as well as suitable plastics, can be refined using technology.

Special coating practices tailored to customers’ needs such as carbon diffusion treatment or titanium nitride are also possible.

The on-site spectrophotometer from Konica Minolta means IsoProfil can precisely measure colour on differently shaped profiles repeatedly.

To obtain detailed information about the surface condition of the profile, the data obtained from the gloss in and gloss out (SCI) measuring methods are used.

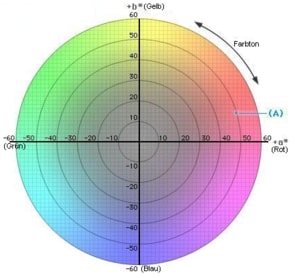

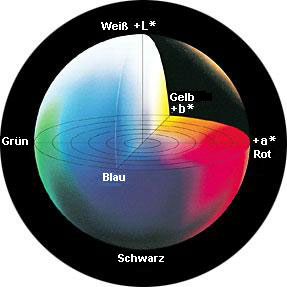

The system most commonly used for colour measurement is the L*a*b* colour system (also called the CIELAB system). The colour space of the L*a*b system is defined by the lightness value L* and the colour coordinates a* and b*.

The colour space is mapped as follows: the a* axis represents the green–red component, with -a* standing for green and +a* indicating red. Accordingly, +b* represents yellow and -b* blue.

The central coordinates (axis intersection point) represent neutral grey. As the a* and b* values increase and the point moves out from the centre, the saturation of the colour rises.

Figure 1 shows the horizontal section at a constant brightness value L*. Figure 2 shows the complete L*a*b* system colour space.

lsoProfile refines the surfaces of your aluminium profiles using electrochemical processes such as anodising. In this process aluminium is converted into aluminium oxide by anodic oxidation. The oxide layer generated increases the corrosion resistance and wear resistance.

> More about anodising

lsoProfil supplies electroplated products made of metal and plastic for a wide range of applications which are coated in the following materials according to customers’ specifications:

> More about electroplated coatings

When gilding, metal profiles and plastic are covered with a layer of gold. Metal like alloys steel, stainless steel, zinc, brass, bronze, copper and silver are particularly suited to this process. Thanks to modern electroplating, there are no limits to the production of special designs, e.g. thick-film coatings or gilding of non-metals!

The results of our work can be seen, for example, on decorative elements in luxury yachts and cars or indeed high-value consumer items.

As an eco-friendly form of dry painting, powder coating results in an exclusive design with top-quality corrosion resistance through the application of coats in one single dip. This process enables a wide variety of optics (surface finishes) and is ideal for decorative profiles.

lsoProfil provides powder coatings in different optics (surface finishes) and colours, including: