By comparison with the extrusion standard defined in DIN EN 12020-2 and DIN EN 755-9, we offer you profiles with a precision that is up to 20 times higher. Depending on the profile geometry, we work in production with very close tolerances down to ± 0.01 mm.

We can offer any desired extruded profile in various shapes and sizes and with optimum surface finish. Other materials, such as brass, copper or steel are also used.

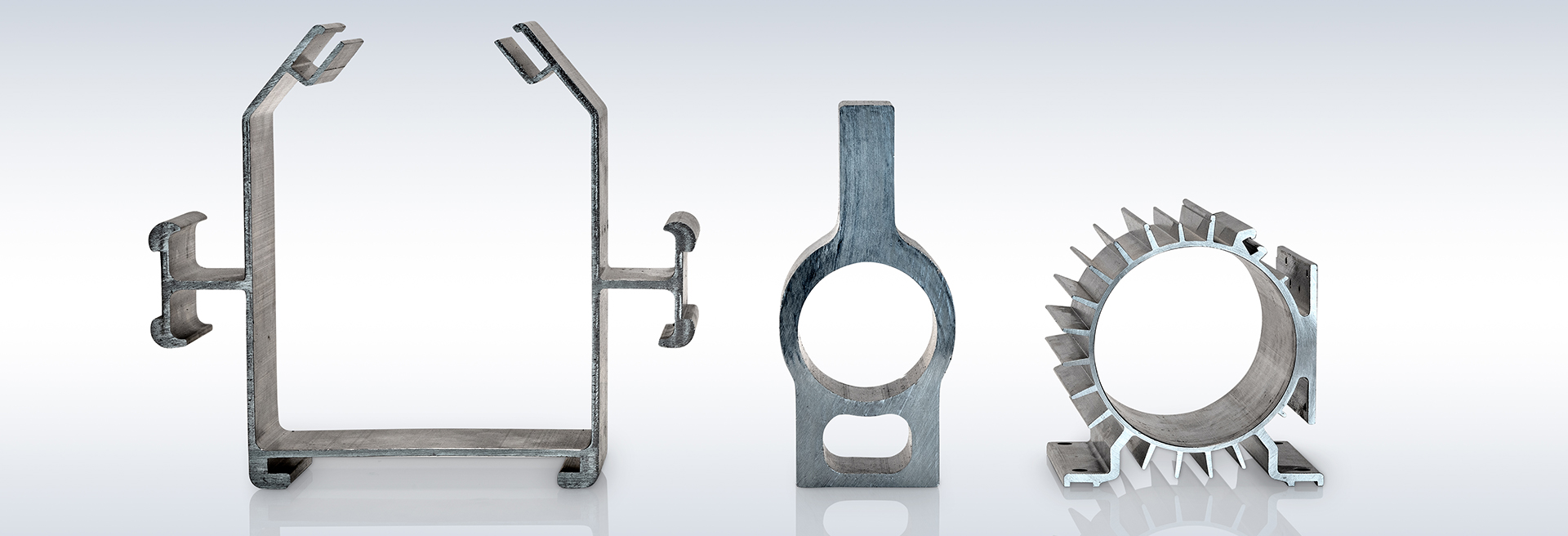

IsoProfil is at your side as an experienced specialist when it comes to the production of extruded aluminium profiles. The extruded aluminium profiles are used in a large number of products and in practically every industry.

Furthermore, our innovative techniques and technologies allow us to produce extruded aluminium profiles with complex forms and sizes, extremely thin walls (e.g. 0.3 mm) and optimum surfaces also suitable for gloss anodising.

Brass profiles are suitable for numerous fields of applications and are manufactured and finished in many different versions and cross-sections. They are used not only in the building industry, but also in living room decoration, interior outfitting and modelmaking. As they are easy to machine, they can be easily formed into a wide range of desired shapes.

Our brass profiles are used, for example, as decorative highlights in aircraft construction and shipbuilding – and particularly in their VIP interior outfitting. In addition they are used in showcases for high-quality exhibits, as façade elements and in the fittings industry.

As an expert for the production of copper profiles and extruded copper profiles, IsoProfil has vast know-how when it comes to the production of copper parts using alternative manufacturing methods. Extruded copper profiles are used in many special branches of industry and in various applications.

Copper extrusion profiles are used for:

Steel alloys have the most varied properties in terms of strength, shapeability, corrosion behaviour and weldability. Steel scrap can be melted down and recycled, thus conserving resources as well as protecting the environment. The addition of steel refiners such as chrome, manganese, cobalt, vanadium, molybdenum, tungsten and niobium simplifies processing or ensures corrosion resistance, as with stainless steel.

The fields of application for steel and stainless steel profiles range from floor covering profiles to building profiles and construction engineering.

The extruded profiles are used in many different products and almost all industries.

Aerospace industry

Shipbuilding industry

Fahrzeugbau

Construction industry

Engineering

Displays

Rolladen

Garages

Carports

and many more

Extrusion means: A pellet (round, oval or rectangular) heated to forming temperature from the desired raw material is pressed by means of a punch, usually hydraulic, under high pressure through the forming die. The outer shape of the extruded profile to be produced is determined by the outer contour of this die.

There are different procedures: Direct and indirect extrusion as well as hydrostatic extrusion, in which the extrusion force is not applied to the billet directly by the die, but by a so-called active medium, such as water or oil. Extrusion is one of the forming processes according to DIN 8582 and is defined in more detail in DIN 8583.

Extruded aluminum profiles are used in almost all industries. In addition to aluminum extrusion, we also offer extrusion profiles in copper, brass & steel.

On request, we will produce a prototype for each of your requirements that still allows for desired modifications. Here you will find all the services that we offer.

That depends entirely on the field of application. We will be happy to advise you on materials, alloys and further demands for your profile. You are welcome to contact us directly.

Learn more about the manufacturing processes we use